The Overlooked Fall Hazards Above the Ladder: Securing the Work, Not Just the Worker

- Michele Oras

- Aug 7, 2025

- 2 min read

Updated: Sep 11, 2025

Most fall protection discussions focus on PPE—harnesses, tie-off points, and personal arrest systems. But real-world rooftop safety often depends on what happens after the worker climbs the ladder.

Too many job sites overlook the dangers involved in how workers access the roof, what they're carrying, and how the job is set up. Here's what gets missed:

1. Unsecured Extension Ladders

Extension ladders are a fall hazard without a solid connection to the structure. Too often, they lean against parapets or flashing without any anchoring. One slip or shift, and the ladder can fall while the worker is still on the roof.

Solution: LadderPort Ladder Receiver

Permanently mounted to the building, LadderPort holds extension ladders securely in place during use—meeting OSHA 1926.1053(b)(1) for ladder stability. It’s a safer alternative to installing a fixed vertical ladder.

2. Roof Hatch Hazards

Most workers leave the hatch open for convenience. That means if there’s no guardrail, the roof now has a 36" hole in it—a fall hazard by any standard. Worse, some safety post systems block the hatch cover, making it impossible to close during use.

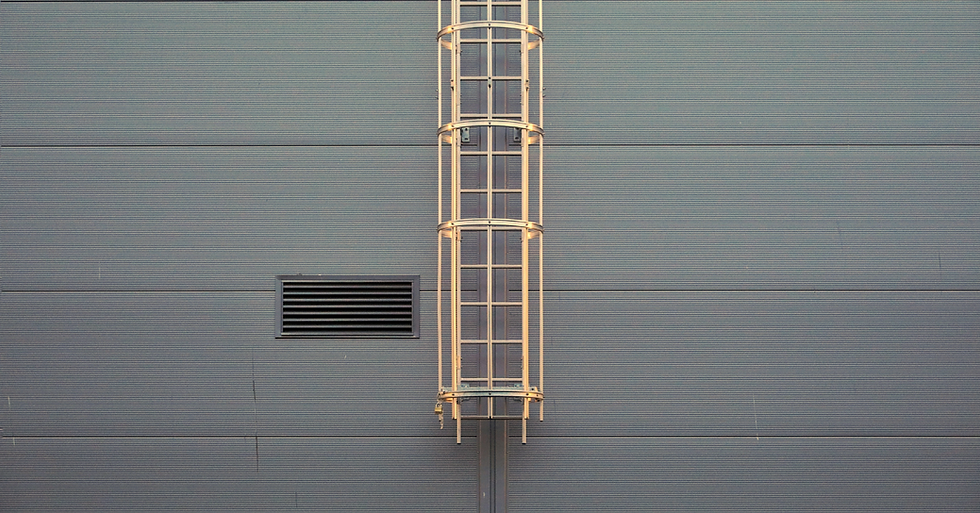

Solution: LadderPort Caged Roof Hatch Grab Bars

Always in place, OSHA-compliant, and obstruction-free. Unlike ladder safety posts, they require no deployment, don’t interfere with ladder use, and don’t block the hatch from closing. Add the optional cage and self-closing gate for full 1910.28(b) compliance—especially critical when the hatch is within 10 feet of a roof edge.

3. Lifting Heavy Equipment Without Control

Contractors often lift motors, compressors, and toolboxes to the roof manually or with makeshift pulleys—a scenario full of fall and strain hazards. One slip or dropped load can injure a worker or damage property.

Renting a crane for small rooftop lifts is often expensive, time-consuming, and complete overkill for routine jobs. It's a logistical headache that most facilities and contractors would rather avoid.

—a scenario full of fall and strain hazards. One slip or dropped load can injure a worker or damage property.

Solution: Cranky Portable Winch & Post

An OSHA-compliant lifting system that mounts to a fixed or portable post. Cranky safely hoists up to 300 lb. with a crank handle, brake, and pulley—allowing one worker to lift without physical strain or risk of losing control.

The Real Fall Protection: Systems That Don’t Rely on Memory

Fall protection fails when it depends on workers remembering steps or operating mechanical devices perfectly. And yet, that’s exactly what many rooftop setups require. Whether it's relying on workers to raise a post, lock a pulley, or find a tie-off point, too much is left to chance.

LadderPort solutions reduce these pain points:

Ladder safety posts require perfect timing and two hands—LadderPort Grab Bars are fixed, no setup needed.

Loose ladders are a serious hazard—Ladder Receivers secure them with a permanent anchor.

Lifting gear by hand or makeshift rigging adds strain and risk—Cranky provides a controlled, single-worker lift system.

Each product is OSHA compliant, Made in the USA, and designed to eliminate failure points in real-world rooftop conditions.

Don't Just Secure the Worker—Secure the Process

PPE is only one piece of the puzzle. Stable ladders, guarded hatches, and controlled lifts prevent injuries before they happen. Upgrade your rooftop safety system today. Call (800) 770-8851 or visit ladderport.com to get a quote.